Our heat shrink tubes are available in a wide range of sizes, dimensions and shrinkage rates and are manufactured using the most advanced methods to ensure that covered products exposed to extreme high temperatures, corrosion, shock, moisture and other critical conditions are perfectly protected and ready to use.

Zeus' heat shrink tubing provides a state-of-the-art method for applying a tight protective layer to items that will be subjected to extreme heat, corrosion, shock, moisture and other harsh environmental conditions. For example, in medical applications, FEP heat shrink tubing is a popular material choice for braiding nylon/Pebax sheath loops together to form finished shafts for catheter designs.®

We manufacture high-performance heat shrink tubing from a variety of polymer resins, including PTFE, FEP, PFA, ETFE, PEEK and PTFE/FEP dual shrink tubing.™. We can customise our heat shrink products to meet your exact specifications in terms of material, shrinkage, tolerances and dimensions.

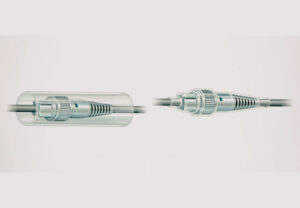

Zeus heat shrink tubes are supplied in an expanded state and can be simply heated to "shrink wrap" complex and irregular shapes. The result is a protective layer that greatly extends the life, improves reliability, and enhances the performance of covered components and parts used in thousands of applications.

Industries We Serve

Zeus heat shrink tubing offers desirable properties including dielectric strength, temperature resistance, chemical resistance, purity, lubricity, and reliability.For more than 50 years, Zeus has been supplying high-performance polymer heat shrink tubing to the medical, electronics, aerospace, automotive, oil and gas, and many other industries.

Medical

For a long time, conduit manufacturers have been calling for a better way to remove heat shrink after the reflow process, and Zeus responded with FluoroPEELZ™, an optically clear peelable heat shrink that increases production and improves worker safety. Through a simple linear tear, operators can quickly and easily remove heat shrink, revealing a smooth surface finish free of defects.

Our heat shrink tubing is also widely used in gastrointestinal/endoscopy applications, and the PTFE Sub-Lite-Wall™ spiral heat shrink tubing has a colour pattern to help doctors manipulate the wire guides through the body's tortuous passages. The heat resistance of the heat shrink tubing is ideal for insulating cautery forceps during biopsies.

General Industry

We are the world's only manufacturer of heat-shrinkable PEEK, known as PEEKshrink.™PEEK Shrinkage™Known for its 500 °F (260 °C) heat resistance as well as its mechanical strength and purity, PEEK Shrinkage™Meets the critical need for secure splicing and insulation of sensitive cabling in aerospace, automotive, and oil and gas applications.

Aerospace Design Engineers Use Our FEP Lay-Flat™Because of their lubricity and reusability, heat shrinks act as seamless release aids for moulded composites. PTFE / FEP Dual Shrink™ provides a tight, moisture-resistant bond on wires, cables, connectors and other components, offers temperature resistance up to 450 °F (232 °C), and withstands severe stresses involving tension and vibration.

Many of our products meet aerospace, automotive, military and commercial standards; in most cases, we exceed the intent of those standards.