As thin as you need it to be (<0.0254 mm/1 mil)

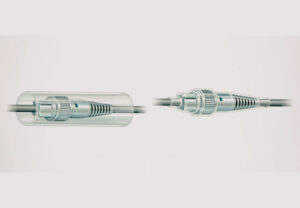

Suggest considering 4:1 heat shrink tubes

Applications

Laser Cut Seawave Tube Sleeves

Outer layer of the conduit shaft

Coating of tapered guide wires

Coil/weave coverings

Key Features

Ultra-flexible and thin-walled

Multiple hardnesses

Rugged and durable

Compatible with thermoplastics and

Metal substrate compatibility

high adhesion

High Shrinkage Ratio

Low vertical shrinkage

Surface finish of outer diameter

Excellent Concentricity

Strong sealing

No need to remove

Specification

Project

Pebax 4:1 Heat Shrink Tube

Polyolefin 4:1 heat shrink tubes

in care of (used on address line after name)Shrinkage Temperature

~ 340° F/171° C

~ 220° F/105° C

durometer

72, 74

63

Elongation at break

300% (for 72D)

Fracture Tension

intensity

7,500 psi

Dielectric Strength

>500 volts/mil

1000 volts/mil

Pipe Certification

Meets USP Class VI

Meets USP Class VI

Anti-bacterial

Highly stable, can be sterilised by gamma rays, electron beams or ethylene oxide. High-pressure sterilisation or re-use testing is possible.

Highly stable, can be sterilised by gamma rays, electron beams or ethylene oxide. High-pressure sterilisation or re-use testing is possible.

Bending Modulus

Varies with hardness

135,000 psi

Key Features

- Ultra-flexible, thin-walled

- Various hardnesses

- With polymers and metals

agglutination

- Maximum adhesive force

- High Shrinkage Ratio

- Excellent Concentricity

- No need to remove

- Tightly closed

- Ultra-flexible, thin-walled

- Fixed hardness

- Very low shrinkage temperature

- Good moisture resistance

- High Shrinkage Ratio

- Excellent Concentricity

- Easy retention, no need

unplug

- Rapid Shrinkage

Standardised stock - technical parameters

(Colour, hardness, expansion ratio, cutting length can be customised)

74D Hardness 4:1 shrinkage ratio PEBAX heat shrink tubing

Inflated inner diameter (min)

Shrunken inner diameter (max)

Post-shrinkage

Wall thickness*

Colour

Product Code

0.060"

(1.50mm)

0.020"

(0.50mm)

0.002"

(0.05mm)

open (non-secretive)

CP4-060-002-74-CLR

72D Hardness 4:1 shrinkage ratio PEBAX heat shrink tubing

0.070"

(1.70mm)

0.021"

(0.50mm)

0.0006" / 0.004"

(0.10mm)

open (non-secretive)

P4-080-004-CLR

0.070"

(1.70mm)

0.021"

(0.50mm)

0.0006" / 0.004"

(0.10mm)

ferrous

P4-080-004-BLK

0.098"

(2.50mm)

0.035"

(0.90mm)

0.0015" / 0.010"

(0.25mm)

open (non-secretive)

P4-120-010-CLR

0.120"

(3.00mm)

0.035"

(0.90mm)

0.0005" / 0.003"

(0.07mm)

open (non-secretive)

P4-120-003-CLR

0.250"

(6.30mm)

0.070"

(1.70mm)

0.0008" / 0.006"

(0.15mm)

open (non-secretive)

P4-280-006-CLR

63D Hardness 4:1 shrinkage ratio POLYOLEFIN heat shrink tubes

0.040"

(1.00mm)

0.010"

(0.25mm)

0.0005" / 0.002"

(0.05mm)

open (non-secretive)

U4-040-CLR

0.040"

(1.00mm)

0.010"

(0.25mm)

0.001" / 0.005"

(0.1mm)

open (non-secretive)

X4-040-CLR

0.080"

(2.00mm)

0.020"

(0.50mm)

0.001" / 0.005"

(0.1mm)

open (non-secretive)

X4-080-CLR

0.080"

(2.00mm)

0.020"

(0.50mm)

0.001" / 0.005"

(0.1mm)

ferrous

X4-080-BLK

0.140"

(3.60mm)

0.035"

(0.90mm)

0.001" / 0.003"

(0.07mm)

open (non-secretive)

U4-140-CLR

0.140"

(3.60mm)

0.050"

(1.30mm)

0.002" / 0.009"

(0.2mm)

open (non-secretive)

X4-140-CLR

0.240"

(6.10mm)

0.060"

(1.50mm)

0.001" / 0.003"

(0.07mm)

open (non-secretive)

U4-240-CLR

0.360"

(9.10mm)

0.090"

(2.30mm)

0.001" / 0.005"

(0.1mm)

ferrous

U4-360-BLK